KLS17-Composite Pipe

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Constructions

These two kinds have their different fields of application. Generally speaking, type B can satisfy even more stringent requirements. They equally comply with ASTM F1281 (ASTM F1282) and ASTM F1335 respectively. Hereabove are just to name a few of many. The potential fields of application for these pipes are really inexhaustible. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Hansen Composite Pipe can also be divided into the following types: Tap water Pipe Hot Water pipe Gas pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Installation Hansen composite pipe has been developed to install tens or even hundreds of meters in succession, it can be bent easily therefore reducing joints greatly. They are easy to use, physically undemanding and time-saving. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advantages | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

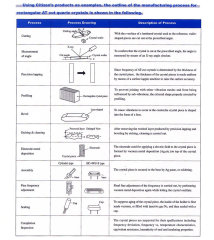

New generation of healthy & environmental-friendly pipe Products: Composite Pipe owns the advantages of both the Plastic and metallic pipe, featuring by small thermal expansion coefficient, greatly reduced friction to flowing liquids, 100% gas-tight, light-weight, easy installation, corrosion and rust-resistant, long service life and sanitarily excellency so on. Developed manufacturing techniques & reasonable pipe construction: Construction of the composite pie is strictly in accordance with ASTM F1335. Comparatively thicker aluminum pipe further pre-conditions the remarkable temperature & pressure-resistant performances of pipe. Welded edge to edge without overlapping, the tube¡¯s metal section is neither oversized nor fragile. Sets of production line imported from Europe: Perfect Quality Control: # microscope---for observation of each layer¡¯s construction, accuracy of testing can be as small as 0.1mm; Besides the above-mentioned equipments, other process testing equipment such as Automatic Widening Device further assures each coil of end pipe products. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

NINGBO KLS IMP&EXP CO.LTD. [China (Mainland)]

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (3509)

- Connectors (252)

- RF Connectors *Antennas (107)

- Audio And video Accessories (449)

- Terminal blocks (279)

- Buzzers (79)

- Potentiometers (48)

- Fuses * Fuse Holders (160)

- Resistors (25)

- Switches (307)

- Wiring Accessories (184)

- LEDs*LED Displays*LCD Displays And Modules (84)

- Capacitors (18)

- KWH Meter Accessories (81)

- Communication Accessories (256)

- Quartz Crystal Units * Ceramic Resonators (27)

- PCB * PCB Assembly (69)

- Flat Cables * Cable Assemblies (272)

- Inductors (21)

- Relays*Discrete Semiconductors (35)

- Others (756)